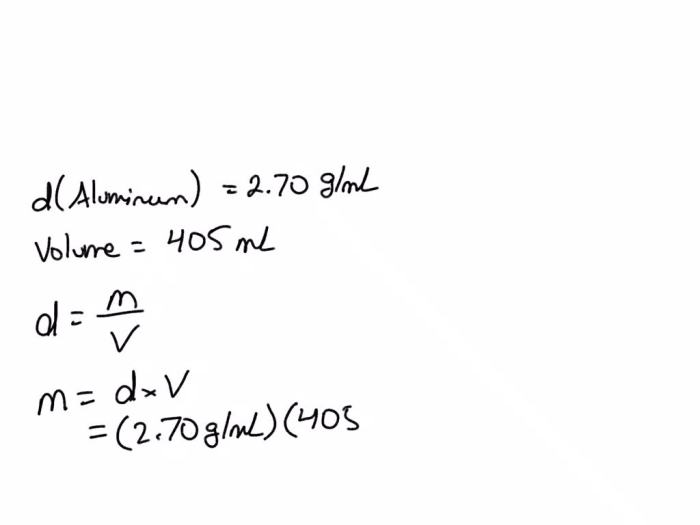

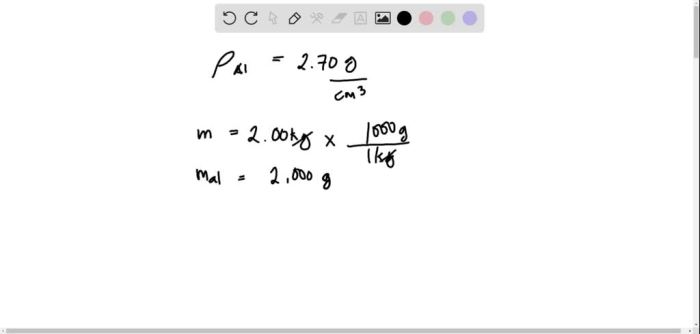

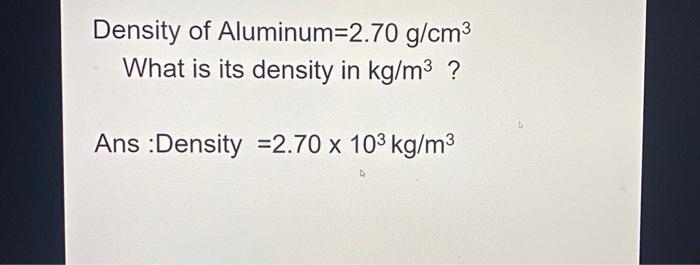

Aluminum has a density of 2.70 g cm3, a property that plays a pivotal role in its diverse applications. This lightweight metal offers a unique combination of strength, corrosion resistance, and formability, making it a preferred choice in industries ranging from aerospace to construction.

Aluminum’s low density enables it to be used in lightweight structures, such as aircraft and automobiles, where weight reduction is crucial. Its high strength-to-weight ratio makes it an ideal material for bridges, buildings, and other architectural applications.

Properties of Aluminum

Aluminum, a lightweight yet robust metal, stands out due to its exceptional properties that make it a versatile material in various industries. One of its defining characteristics is its low density, which plays a significant role in its widespread applications.

Physical Properties

Aluminum possesses a density of 2.70 g cm 3, making it remarkably lightweight compared to other common metals like iron or copper. This low density contributes to its high strength-to-weight ratio, enabling the creation of lightweight structures without compromising durability.

Chemical Properties

Aluminum exhibits high corrosion resistance due to the formation of a protective oxide layer on its surface. This layer effectively shields the metal from further oxidation, making it resistant to rust and other forms of corrosion. Additionally, aluminum is non-toxic and non-magnetic, further enhancing its versatility in various applications.

Significance of Density

The low density of aluminum has significant implications for its applications. In the transportation sector, it is widely used in the manufacturing of aircraft, automobiles, and other vehicles, where weight reduction is crucial for fuel efficiency and performance.

In construction, aluminum’s lightweight nature allows for the creation of lightweight and durable structures, such as bridges, buildings, and roofing systems. It also finds applications in packaging, electronics, and other industries where weight optimization is essential.

Comparison to Other Metals

Aluminum’s density of 2.70 g/cm³ is relatively low compared to other common metals, making it a lightweight material. This property offers both advantages and disadvantages in various applications.

Density Comparison Table

The following table compares the density of aluminum to other common metals:

| Metal | Density (g/cm³) |

|---|---|

| Aluminum | 2.70 |

| Steel | 7.85 |

| Copper | 8.96 |

| Titanium | 4.51 |

Advantages of Aluminum’s Density

Aluminum’s low density provides several advantages, including:

- Lightweight:Aluminum is significantly lighter than most other metals, making it suitable for applications where weight reduction is crucial, such as aerospace and transportation.

- High strength-to-weight ratio:Despite its low density, aluminum offers a high strength-to-weight ratio, making it suitable for structural applications where strength is required without excessive weight.

- Corrosion resistance:Aluminum forms a protective oxide layer that enhances its corrosion resistance, making it suitable for applications in harsh environments.

Disadvantages of Aluminum’s Density

While aluminum’s low density offers advantages, it also has some disadvantages:

- Lower strength than other metals:Aluminum is generally less strong than other metals such as steel or titanium, limiting its use in applications requiring high strength.

- Susceptibility to creep:Aluminum is susceptible to creep, which is the gradual deformation of a material under sustained load, limiting its use in applications involving long-term loading.

Specific Applications

Aluminum’s unique combination of properties makes it the preferred choice for various applications, including:

- Aerospace:Aluminum’s low density and high strength-to-weight ratio make it ideal for aircraft and spacecraft components.

- Automotive:Aluminum is used in automotive parts, such as engine blocks and body panels, to reduce weight and improve fuel efficiency.

- Construction:Aluminum is used in building materials, such as siding and roofing, due to its lightweight, corrosion resistance, and durability.

- Consumer products:Aluminum is found in a wide range of consumer products, such as beverage cans, food packaging, and cookware, due to its lightweight, recyclability, and corrosion resistance.

Applications of Aluminum

Aluminum is widely used in various industries due to its exceptional combination of properties, including its low density. The density of aluminum (2.70 g cm 3) makes it a lightweight material that offers advantages in applications where weight reduction is critical.

The following are some major applications of aluminum, highlighting those where its density is a key factor:

Aerospace

- Aircraft:Aluminum’s low density and high strength-to-weight ratio make it an ideal material for aircraft construction. Its use in aircraft components, such as fuselages, wings, and skins, helps reduce the overall weight of the aircraft, improving fuel efficiency and performance.

- Rockets:Aluminum is also used in rocket construction, particularly in fuel tanks and structural components. Its lightweight nature allows for increased payload capacity and improved fuel efficiency.

Transportation, Aluminum has a density of 2.70 g cm3

- Automobiles:Aluminum is increasingly used in automobiles to reduce weight and improve fuel efficiency. It is used in various components, including body panels, wheels, and engine parts.

- High-speed trains:Aluminum’s low density and high strength make it suitable for high-speed trains. Its use in train bodies and components contributes to reduced weight, increased speed, and energy efficiency.

Construction

- Building facades:Aluminum is widely used in building facades due to its lightweight nature and durability. Its use in curtain walls, cladding, and roofing systems helps reduce the overall weight of the building and improve structural integrity.

- Windows and doors:Aluminum is also used in windows and doors because of its low density and high strength-to-weight ratio. These properties enable the creation of large, lightweight windows and doors that are durable and energy-efficient.

Packaging

- Beverage cans:Aluminum is the primary material used in beverage cans due to its lightweight nature and recyclability. Its low density allows for the production of thin-walled cans that are lightweight and easy to transport.

- Food packaging:Aluminum is also used in food packaging, such as foil and containers, due to its ability to protect food from light, oxygen, and moisture.

Challenges and Opportunities

Aluminum’s low density offers significant advantages, but it also presents challenges in certain applications. This section will explore the limitations and potential opportunities associated with aluminum’s density.

One challenge is the reduced strength-to-weight ratio compared to denser metals like steel or titanium. This can limit the use of aluminum in applications requiring high strength, such as structural components or armor.

Research and Development Directions

- Alloy development:Research is ongoing to develop new aluminum alloys that enhance strength while maintaining low density. By modifying the composition and microstructure, engineers aim to improve mechanical properties without compromising weight.

- Surface treatments:Techniques like anodizing and thermal spraying can enhance the surface hardness and wear resistance of aluminum, making it more suitable for demanding applications.

- Composite materials:Combining aluminum with other materials, such as carbon fiber or ceramics, can create lightweight composites with improved strength and stiffness. This approach offers potential in industries like aerospace and automotive.

- Design optimization:Engineers are exploring innovative design approaches to maximize the strength and stiffness of aluminum structures while minimizing weight. This involves optimizing geometry, using advanced analysis tools, and leveraging topology optimization techniques.

Sustainability Considerations: Aluminum Has A Density Of 2.70 G Cm3

Aluminum’s high density poses unique challenges and opportunities for its sustainable use. Its production and recycling processes have environmental implications that must be carefully considered.

Life Cycle Assessment of Aluminum

Life cycle assessment (LCA) evaluates the environmental impact of a material throughout its life cycle, from raw material extraction to end-of-life disposal. Aluminum’s LCA reveals that its production is energy-intensive, contributing to greenhouse gas emissions. However, recycling aluminum significantly reduces its environmental footprint compared to primary production.

Environmental Impact of Aluminum Production

Primary aluminum production involves the electrolysis of alumina, a process that requires large amounts of electricity. This electricity generation can contribute to air pollution and climate change, especially if it relies on fossil fuels.

Environmental Impact of Aluminum Recycling

Recycling aluminum is significantly less energy-intensive than primary production. It involves remelting and purifying scrap aluminum, which reduces greenhouse gas emissions by up to 95%. Recycling also conserves natural resources and reduces the need for mining.

Recommendations for Improving Sustainability

To improve the sustainability of aluminum’s use, considering its density, the following recommendations are proposed:

- Increase the use of recycled aluminum in various applications.

- Develop more efficient and low-carbon aluminum production technologies.

- Promote the use of aluminum in lightweight applications where its density advantage can reduce overall environmental impact.

FAQ Resource

Why is aluminum’s density important?

Aluminum’s low density makes it a lightweight material, which is crucial in applications where weight reduction is essential, such as in aerospace and transportation.

How does aluminum’s density affect its strength?

Despite its low density, aluminum is a strong material due to its high strength-to-weight ratio. This makes it suitable for structural applications where strength is required.

What are some common applications of aluminum?

Aluminum is used in a wide range of applications, including aircraft, automobiles, construction, packaging, and consumer electronics.